|

In 1966, a report published by the UK

Department of Education and Science introduced the concept of

tribology, which was defined as the science of interacting surfaces in

relative motion. Tribology, as a “new science” studies friction, wear, and

lubrication. These three processes affect each other with interacting

causes and effects: tribology is the study of them as they interact. The term tribology comes

from Greek words tribos meaning rubbing or sliding and

logos meaning science. After an initial period of scepticism,

as is inevitable for any newly introduced word or concept, the word

“tribology” has gained gradual acceptance. As the word tribology is

relatively new, its meaning is still unclear to the wider community and

humorous comparisons with tribes or

tribolites tend to persist as soon as the word “tribology” is

mentioned.

The tribology is one of the many new

technical disciplines whose development has a great influence on the

reliability and life of mechanical systems. Interdisciplinary character of

the tribology and presence of tribological processes in most of mechanical

systems demand researches in all fields of industry. This is especially

important in transportation, machine production industry, ferrous and

non-ferrous metallurgy and power plants,

where these tribological activities achieve significant technical and

economical effects. The great losses in industry and transportation

because of friction and especially wear of the material are the best

stimulation for tribology development. The biggest contribution of the

tribology is noticeable in materials, design of machine elements and

systems and their maintenance.

Tribological constraints are not

confined only to mechanical equipment. Computers and electronic equipment

are also a fertile source of tribological problems yet to be solved. A

major limitation of data transmission is that for data transfer from a

memory disk to a recording head, sliding contact must occur between the

disk and the head. If there is, however, true solid to solid contact

between these two parts then transferred data will be affected and

degraded by wear damage. The human body itself is also prone to friction

and wear problems. The human joints are perfect bearings lubricated by

synovial fluid and operating

usually without failure for a very long time. In a healthy human joint, an

extremely low coefficient of friction is maintained, values as low as

0.005 have been measured. It has also been shown that the synovial fluid

effectively prevents contact between the joint surfaces. However, when

rheumatism and in particular arthritis occurs fragments of cartilage and

bone are observed in the synovial fluid. These particles are wear

particles generated during the operation of the joint, and like other wear

particles could induce serious damages. |

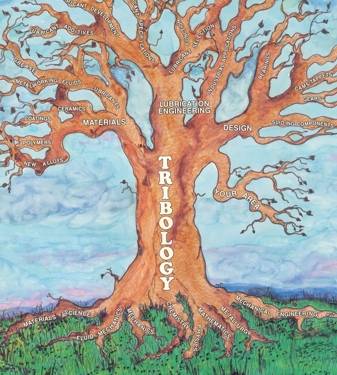

Tribology tree |